Explosion-proof certification is the work used to determine that equipment meets the requirements of explosion-proof standards, type tests and routine tests for adaptation, and issue relevant certificates of conformity. Certificates can be for Ex equipment or Ex components.

There are three main types:

1. China explosion-proof product certification: China implements the "explosion-proof certificate" certification system for explosion-proof electrical products. According to the GB3836 and GB12476 series of national standards, through the review of product design drawings and other documents, prototype inspections and experiments, it is confirmed that the products meet the standards. A certification system that requires and issues an explosion-proof certificate.

2. IEC Ex system: It is an international conformity assessment system for explosion-proof electrical equipment and related services for explosive atmospheres. It is an internationally accepted method to show that explosion-proof electrical equipment or services comply with the IEC TC31 standard.

3. ATEX certification: It is a system for conformity assessment of explosion-proof products specified by EU ATEX, which belongs to one of CE certification.

explosion conditions

Dangerous and explosive substances: gas (gas and combustible dust, gas mixture), liquid (flammable liquid, liquid that emits dangerous gas), solid (powder, block) oxygen (air) detonation source Basic methods to prevent explosion

Avoiding the formation of an explosive atmosphere (the ideal method, it is difficult to achieve) excludes and eliminates possible sources of explosion (a practical method) and restricts one or more of these elements, all of which can meet the explosion-proof requirements. For example, the definition of positive pressure, explosive gas concentration monitoring, limiting ignition source (main means) of explosive hazardous locations

In petroleum, chemical, coal and other production fields, explosive hazardous environments will inevitably be formed, such as:

In coal mines, two-thirds of the sites are explosive hazardous sites; in oil mining sites and refineries, about 60% to 80% are explosive hazardous sites; in the chemical industry, more than 80% of production workshops are explosive Hazardous location. Explosion-proof group and explosion-proof area classification

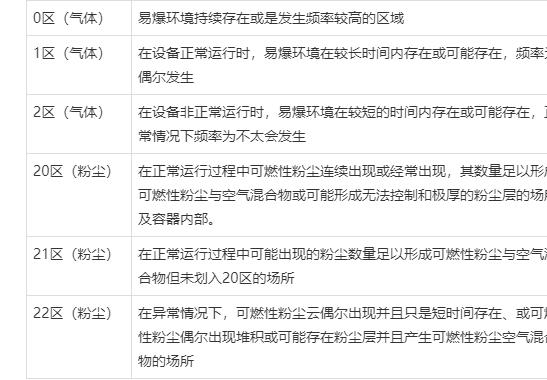

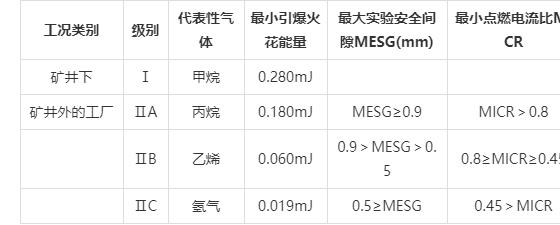

Mining Group Ⅰ Non-mining Group Ⅱ Explosion-proof area classification

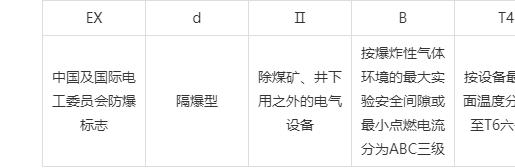

Explosion-proof mark introduction

Generally, in a flammable gas environment, explosion-proof products must be used when using electrical products. The shell of explosion-proof products generally has the following signs, with the specific meanings as follows:

Ex d Ⅱ B T4

The first digit code:

Ex——Explosion-proof mark of China and International Electrotechnical Commission;

EEx - means the European Community;

AD - Italy;

MS, AE - France;

FLP - United Kingdom;

UL, FM - the United States;

E - Germany\IEC

② bit code

3rd bit code

Ⅰ——Coal mine and underground electrical equipment

Ⅱ - Factory electrical equipment

4th digit code

Classification of Class II Explosive Gas Environments

⑤ digit code

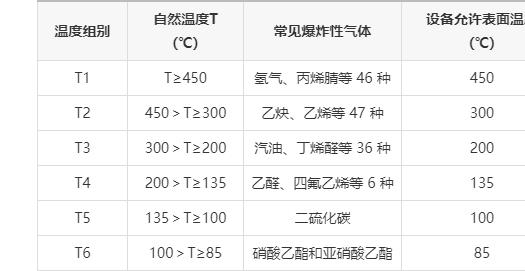

Temperature Groups of Electrical Equipment in Class II Explosive Gas Environments